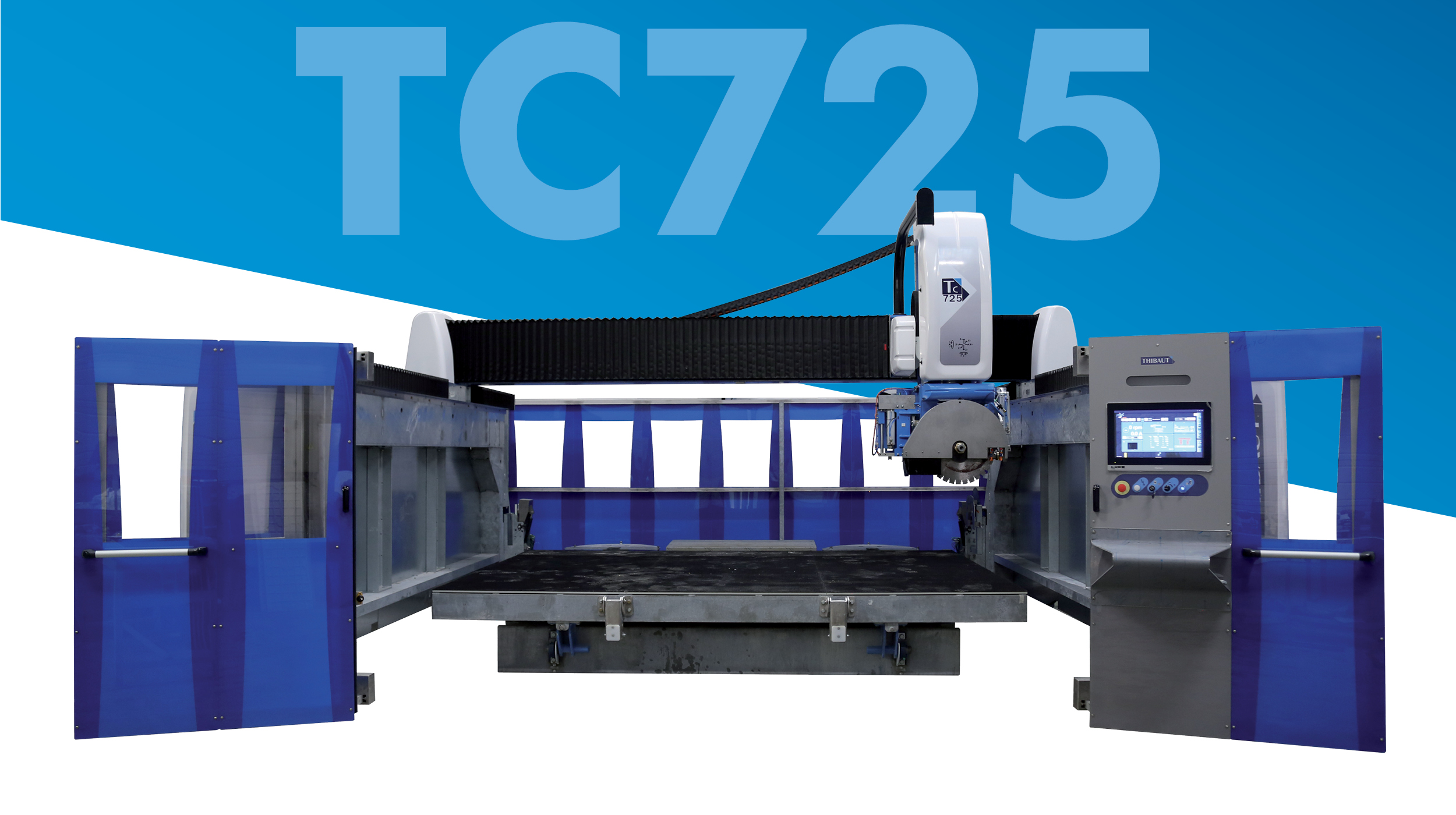

The TC725 is a true 5-axis numerically controlled sawing and shaping centre. The TC725 can automatically cut in all directions up to 250 mm thick or profile workpieces of all shapes. The 360° rotation of the head does not require a rotary table, which makes it a very compact machine.

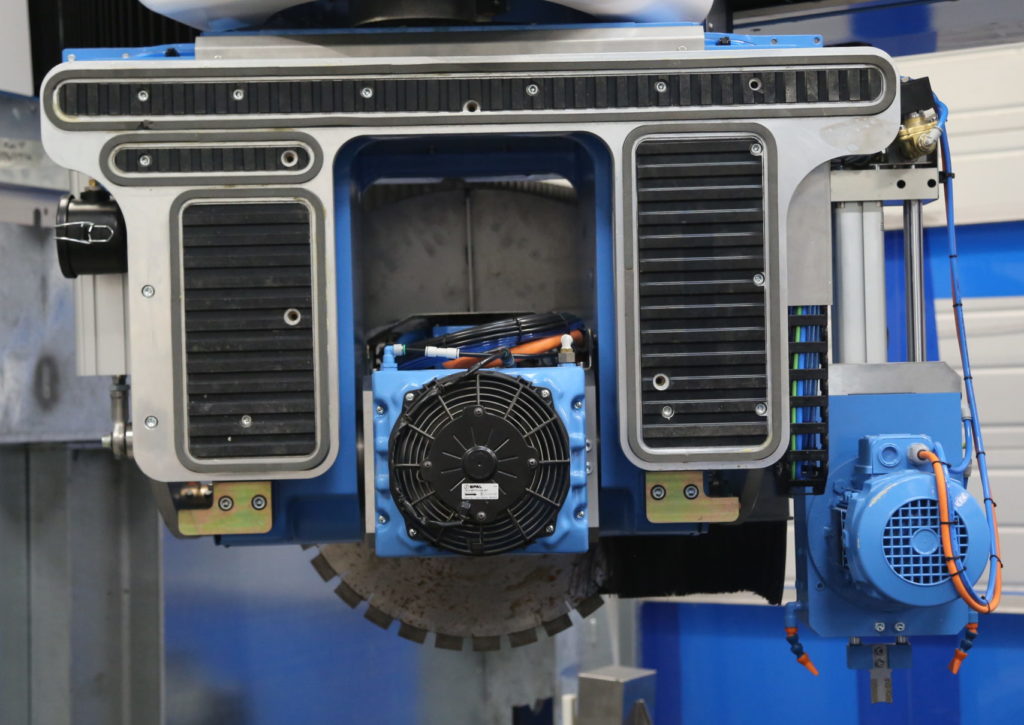

Powerful, the TC725 has a spindle up to 19.9 kW (S6). Its variable speed from 0 to 6000 rpm and its various options give it a very high degree of autonomy and allow it to carry out all types of operations such as drilling, profiling, trimming, sawing, mitre cutting, and brushing, etc.

| Working capacity | mm |

|---|---|

| Stroke X | 3700 |

| Stroke Y | 3700 |

| Stroke Z | 700 |

| Sawing capacity | mm |

|---|---|

| Cutting thickness | 250 |

| Min. disc diameter | 350 |

| Max. disc diameter | 750 |

| Axes | Speed m/min |

|---|---|

| X | 40 |

| Y | 40 |

| Z | 15 |

A-axis tilt: 0°/90°

C-axis rotation: ±200°

Spindle motor power: 19.9kW (S6)

Tool rotation speed: 0/6000 tr/min

Total weight: 7300 kg

| Cross Laser | Line Laser |

| Mechanically welded walls | Quick-opening housing |

| Touch-screen remote control | Working table 3600x2000mm |

| Retractable front stops | Machine doors with 19″ console |

| Electrical cabinet | 1/2 gas adapter for tools |

| Watering for milling tools | Large size flange |

| Camera | Abrasive stone for tool sharpening |

| ACS (Angle Cut Solution) | AVS (Automatic Vacuum Solution max. 750kg) |

| Tilting table | Slab thickness sensor |

| Disc case magazine | Disc magazine |

| Linear 8 tools magazine |

Included:

| Pilot® | Interface developed by Thibaut

|

| Express Jobs | Powerful program including parametric shapes, very easy to use |

| T’Shape 3D shaping software |

| T’Cut 2D cutting software |

| Vein Matching Software Software for 3D visualization of pieces with their veins |

| eT’CAM 2D shaping software designed for decoration |

| T’CAD/T’CAM 3D design and shaping software |

M: A mechanically welded structure consisting of low walls on feet

TOPS (Thibaut Optimized Processing Solution): through-feed system to optimize the production of slabs

Our machines are connected to the internet and equipped with remote connection software with a firewall. This allows quick diagnosis and remote intervention by our Thibaut Customer Service technicians.

A Thibaut Customer Space will give you access to the available documentation of your Thibaut machines and you can make your requests to Thibaut Customer Service.

Quickly request a quote from your sales representative or via the contact form.