A bridge saw or also called a sawing machine or cutting centre for natural stone or ceramics is a very large saw that runs on a beam or bridge. This guarantees professional quality cuts. Bridge saws are used to cut stone, granite, marble, ceramics and all other types of slabs. This cutting is called secondary cutting and takes place after the primary sawing carried out by diamond wire machines or diamond blades.

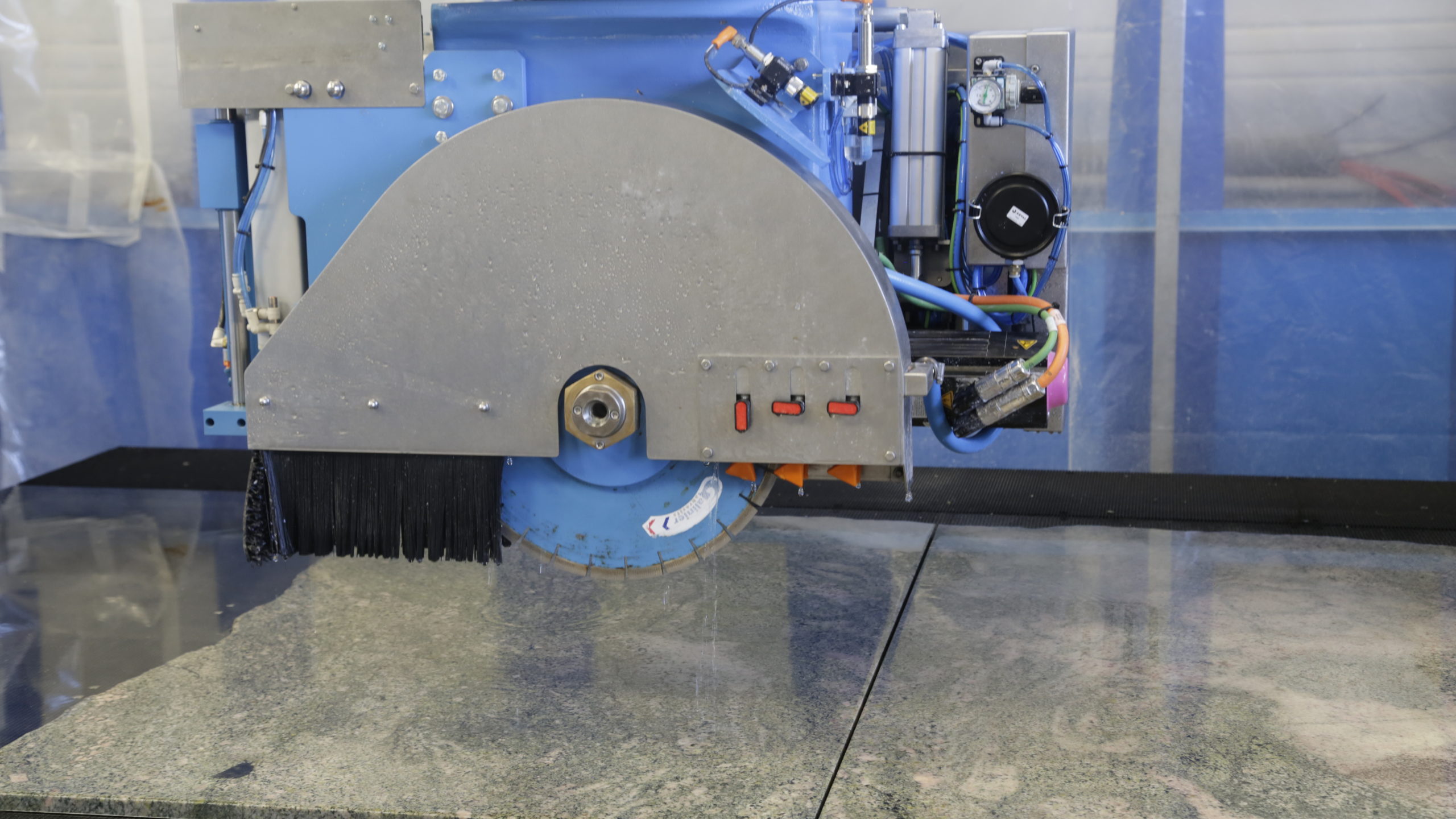

Several components make up a bridge saw. The sawing part with the power of the motor, the size of the diamond disc and the axes of movement. The 5-axis bridge saws are the most powerful because they can cut the stone in any position around the vertical axis.

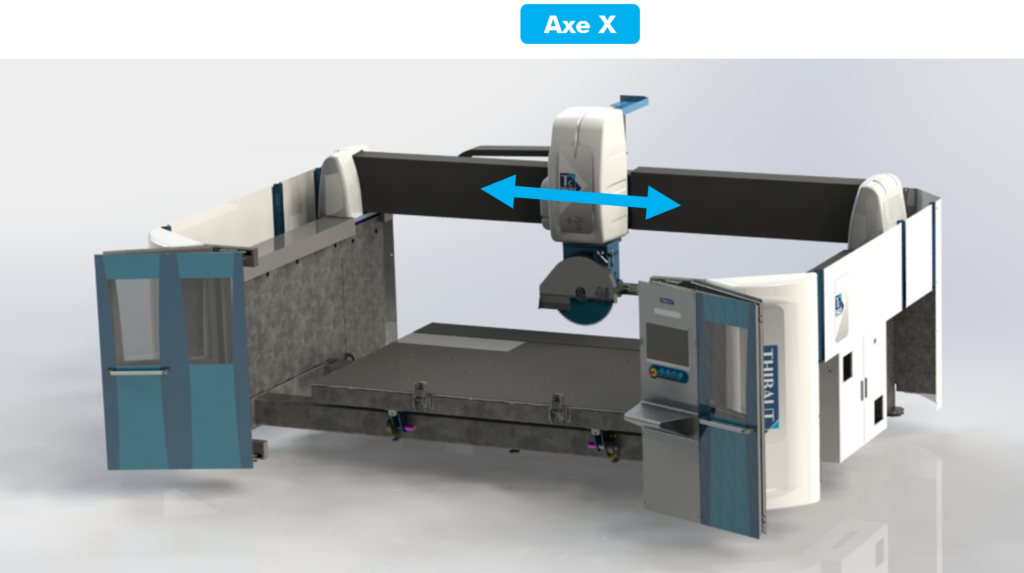

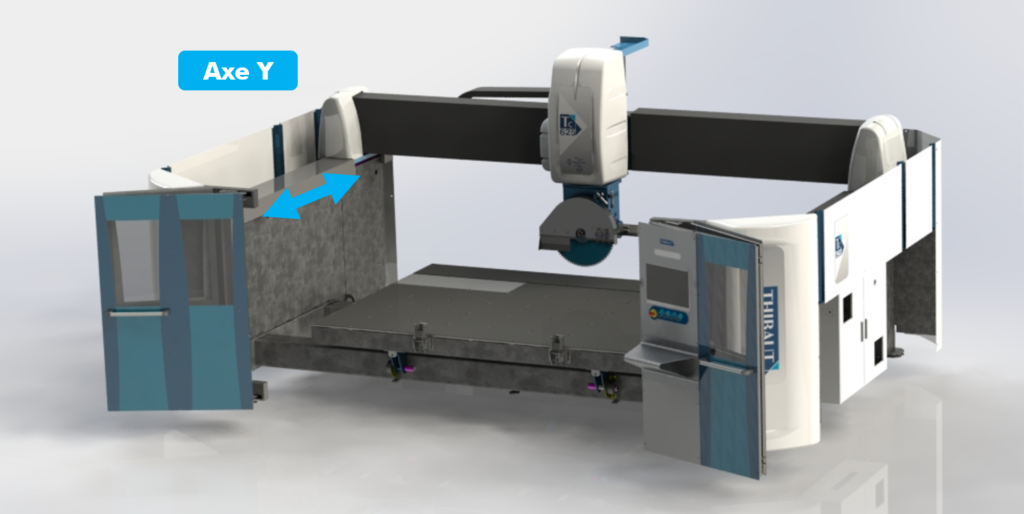

The frame consists of a bridge, hence the name bridge saw, and is moved at the ends by motors. The movement of the bridge is thus carried out on the X and Y axes. There are 2 different structures for bridge saws in the field of stone: a metallic structure of a single block called "monobloc" and a structure with concrete walls. The metal structure makes it easier to move the saw when moving or reorganizing the workshop. However, it is preferable to reinforce the rigidity of the machine with concrete walls in case of cutting large thicknesses.

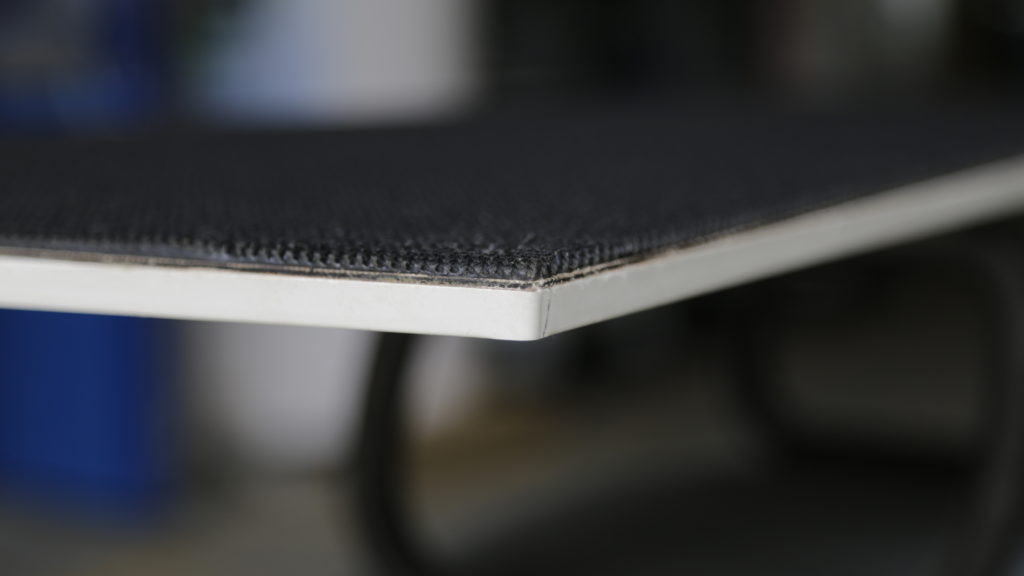

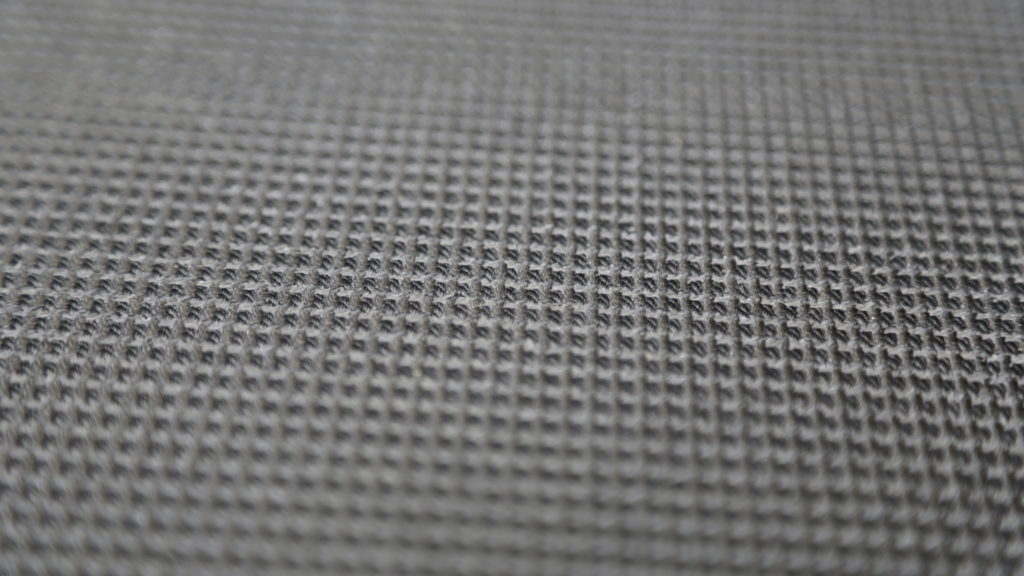

Another important part of a 5-axis bridge saw is the table. Wooden tables can be found on low and mid-range models. On top-of-the-range models such as Thibaut saws, you will find a resin and rubber table that is much more resistant and reliable, unlike wood, which is a "living" material and must be changed regularly to maintain optimum cutting performance. Some tables are therefore motorized and allow rotation or tilting to facilitate the handling of the stone slices to be cut.

Finally, there are manual or automatic bridge saws: these are numerically controlled sawing machines known as CNC. The CNC sawing centre allows different cuts to be made automatically, such as angle or profile cuts.

The main function of a 5-axis bridge saw is the straight cutting of stone. A slab is placed on the table to be cut.

Some cutting machines, such as the 5-axis machines designed more specifically for marble working, are equipped with a head capable of turning on itself and programmable in multiple positions. They thus offer the possibility to follow practically all profiles and to make the special recess and corner cuts encountered in marble work (kitchen and bathroom tops, curved chimney lintel, etc.).

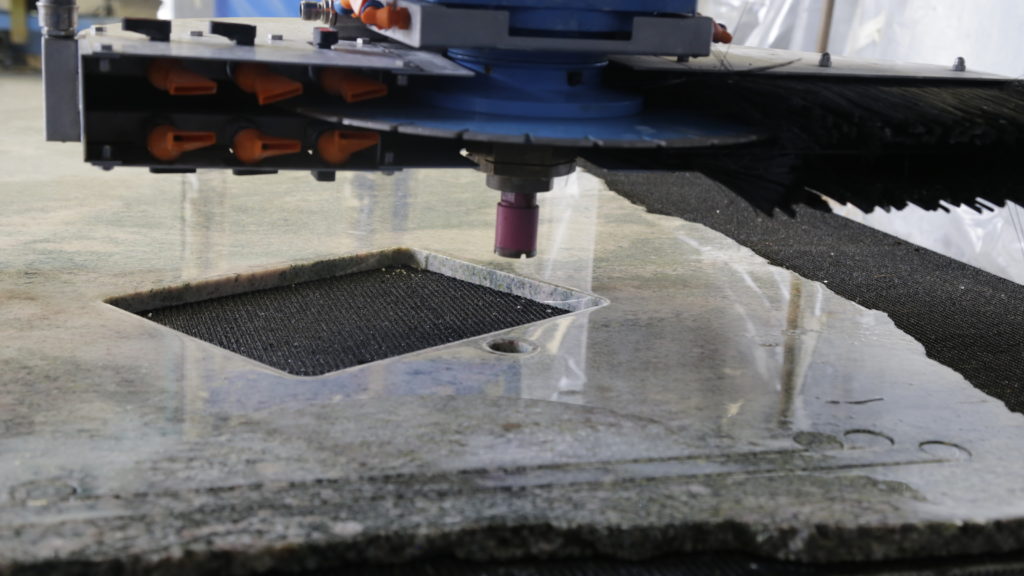

The versatility of a 5-axis bridge saw like the Thibaut TC625 allows cutting in all directions as well as angles for kitchen worktops cutting problems. (Example: cutting sink bowls). With a new generation 5-axis bridge saws, you can cut square, round or oval sink bowls. Indeed, the 5-axis sawing centre has a 1/2 gas attachment that allows you to connect additional tools to the diamond disc: a routing cutter or a drill bit.

This machine can also be completed with one of the vacuums to move the automatic pieces and a jigsaw to finish the corners without human intervention.

The manufacturer Thibaut is recognized as one of the leading manufacturers of stone machinery worldwide. Based in Vire, France, Thibaut's core values are innovation, quality and client support.

The company was founded in 1949 and has been a leading company for over 60 years.

THIBAUT's strength is to offer its clients wide choice among a range of 35 different machines: machining centres, multifunction machines, cutters, polishers, diamond wires and others, designed to shape all types of materials.

Introduction The stone industry has experienced a significant transformation with the introduction of 5-axis bridge saws. Among the leaders in this field, THIBAUT stands out for its innovation and quality. In this article, we will explore the advantages of 5-axis bridge saws for stone, the unique features of THIBAUT machines, and how they can revolutionize […]

Read moreIntroduction to 5-Axis Cutting The 5-axis cutting technology is a major innovation in the ceramic and stone cutting industry. Unlike traditional cutting machines, 5-axis machines like the THIBAUT TC425 offer unparalleled flexibility and precision. This technology allows for complex cuts and sophisticated shapes, ideal for kitchen and bathroom countertops. Thanks to multi-directional cutting capability, professionals […]

Read moreWe are delighted to inform you that Thibaut, a leader in stone processing machinery, will be participating in Stone+tec 2024, which will take place from June 19th to 22nd in Nuremberg, Germany. This prestigious event brings together experts from the natural stone and stone technology fields, providing a unique platform for idea exchange, discovering new trends, and showcasing the latest […]

Read more