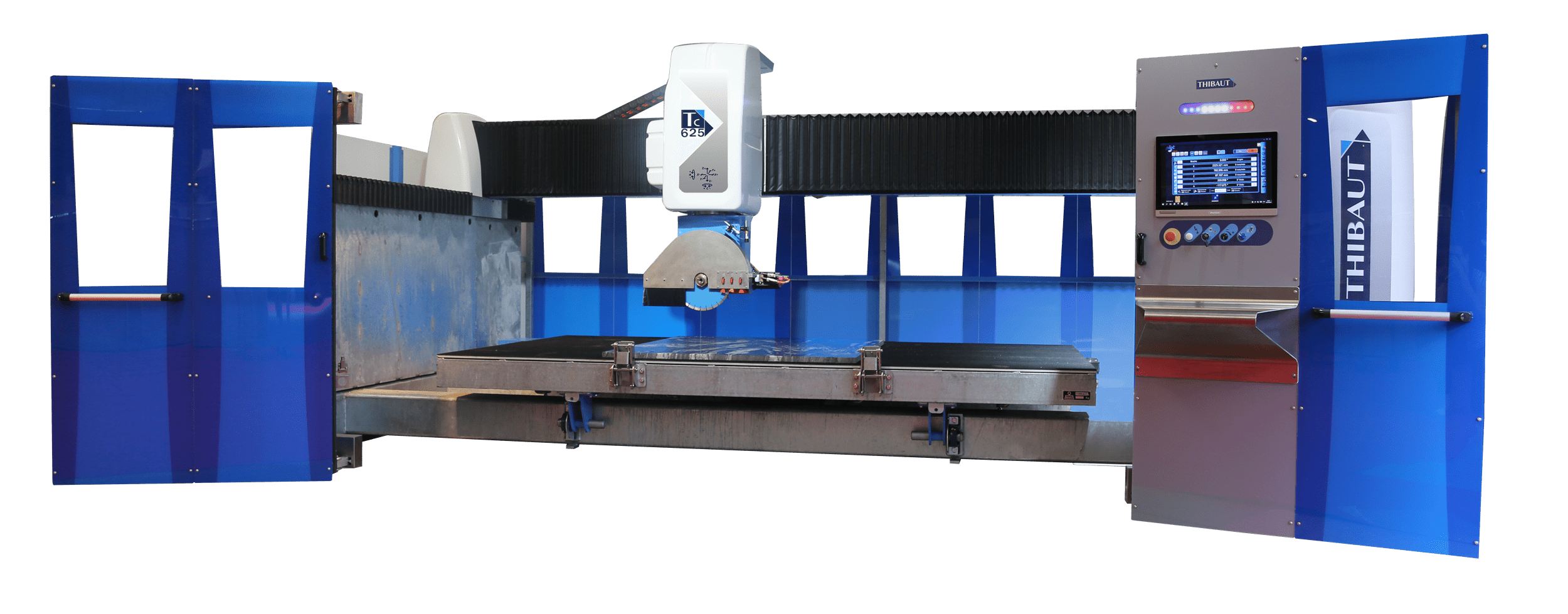

The stone industry has experienced a significant transformation with the introduction of 5-axis bridge saws. Among the leaders in this field, THIBAUT stands out for its innovation and quality. In this article, we will explore the advantages of 5-axis bridge saws for stone, the unique features of THIBAUT machines, and how they can revolutionize your operations.

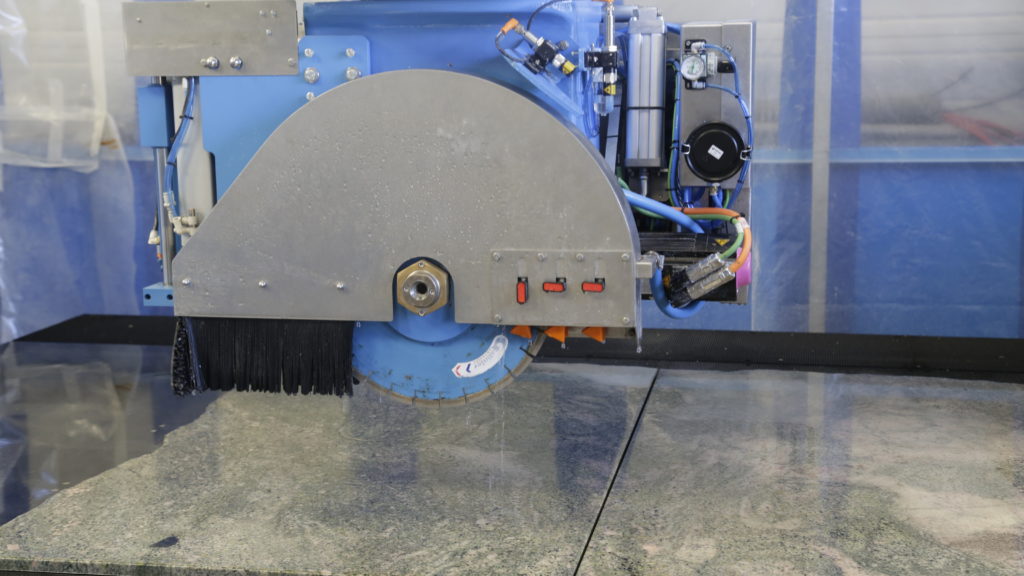

A 5-axis bridge saw is a cutting machine that allows movement along five different axes. Unlike traditional 3 or 4-axis saws, a 5-axis bridge saw offers increased flexibility and precision, making it ideal for complex cuts and detailed projects. These machines can cut at various angles and directions, providing unparalleled versatility in stone cutting. Discover our 5-axis bridge saw.

THIBAUT is renowned for its high-quality machines and constant innovation in the field of stone cutting. Here are some features that make THIBAUT's 5-axis bridge saws exceptional:

THIBAUT's 5-axis bridge saws are used in various industries, including:

A traditional stone cutting company recently integrated a THIBAUT 5-axis bridge saw into its workshop. The result? A 30% increase in productivity and a significant reduction in material waste. Thanks to the machine's precision, they were able to take on more complex and larger-scale projects, increasing their annual revenue. This case study demonstrates the tangible benefits that THIBAUT's technology can bring to a business, enhancing both efficiency and profitability.

5-axis bridge saws for stone represent a major technological advancement for industry professionals. With machines like THIBAUT's, the possibilities for creation and efficiency are virtually limitless. Investing in a THIBAUT 5-axis bridge saw means choosing quality, precision, and innovation to propel your business to new heights.

To learn more about THIBAUT's 5-axis bridge saws and discover how they can transform your operations, contact our team today or visit our website. Discover the future of stone cutting with THIBAUT and experience the benefits of advanced technology in your projects.

We are excited to announce our Targeted Days, a special event taking place from November 4th to 8th, 2024, at our headquarters in Vire. This is a unique opportunity to discover our latest innovations and connect with our experts in a friendly atmosphere. During this event, we will be showcasing two brand-new machines: You will […]

Read more24-Sep-2024 – 27-Sep-2024 Marmomac 2024, the largest trade fair for natural stone Thibaut, the recognized leader in the manufacturing of machines for the processing of natural stone, is delighted to announce its participation in Marmomac 2024. This must-attend event will take place from September 24 to 27 in Verona, Italy, and will bring together the […]

Read moreIntroduction to 5-Axis Cutting The 5-axis cutting technology is a major innovation in the ceramic and stone cutting industry. Unlike traditional cutting machines, 5-axis machines like the THIBAUT TC425 offer unparalleled flexibility and precision. This technology allows for complex cuts and sophisticated shapes, ideal for kitchen and bathroom countertops. Thanks to multi-directional cutting capability, professionals […]

Read more