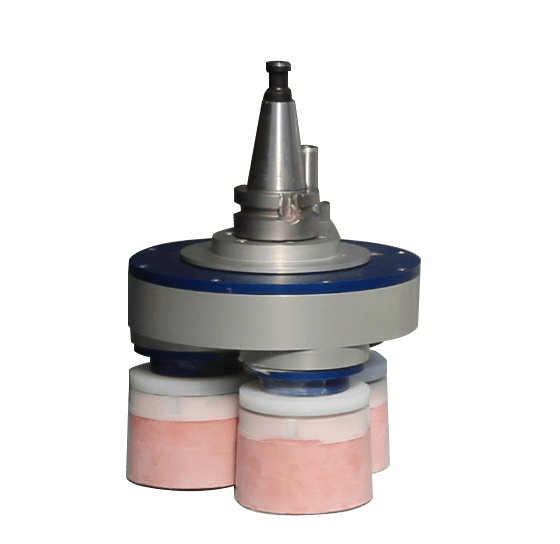

The "satellite" polishing head is used to polish and calibrate flat surfaces. It allows to obtain a very high polishing quality while having a high output. Its head has a diameter of 215 mm and is equipped with a BT 40 cone. The three abrasives have a maximum height of 70 mm. You can use conventional abrasives or resin abrasives. For textured surfaces, it is preferable to use the B3 head instead. The satellite head is compatible with several THIBAUT machines (only on THIBAUT): T108S, T818 M4 and M5, T812, T858V2, T658, T958.

- Light and robust.

- Adaptable on many THIBAUT machines.

- Quality of polishing guaranteed.

- Easy to implement. *

- Economical & efficient: polishing with 5 grains maximum

- (diamond, 120, 400, 800, F).

- Uses conventional abrasives or resins.

- 1 Head Ø 215 mm equipped with a BT 40 attachment, for polishing granite.

- Quick setup with FRF type screws for 3 abrasives (resin or diamond) Ø100 mm.

- Maximum abrasives height 70 mm.

- Weight of the head and attachment: 10 kg.

- Wrench for abrasive coupling included.

- Possibility of installing brushes for texturing.

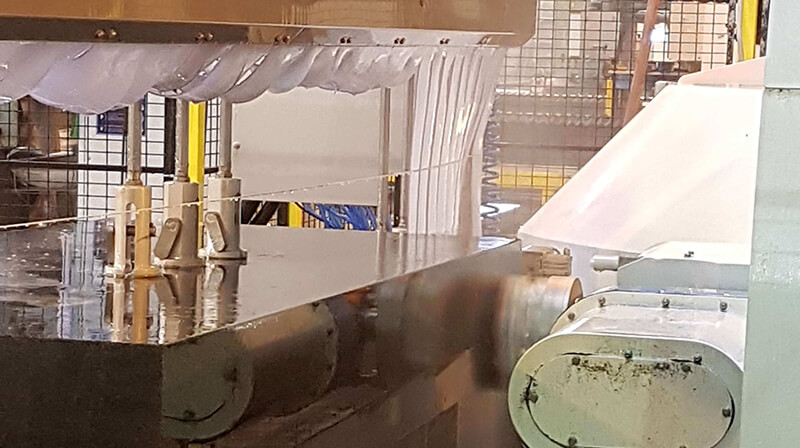

For polishing flat surfaces.1 revolution restraining device, 1 protection cover

For polishing flat surfaces, straight or inclined edges, straight or reducing chamfers, 1 tool holder for positioning the head in the magazine

For polishing flat surfaces. Manual mounting exclusively.

For polishing flat surfaces. 1 tool holder for positioning the head in the magazine.

For polishing flat surfaces, straight or inclined edges, straight or reducing chamfers... 1 tool holder for positioning the head in the magazine.

For polishing flat surfaces, straight or inclined edges, straight or reducing chamfers... 1 tool holder for positioning the head in the magazine.

For polishing flat surfaces, straight or inclined edges, straight or reducing chamfers... 1 tool holder for positioning the head in the magazine.

* Whatever the machine on which the head is installed, an anti-rotation system is required.

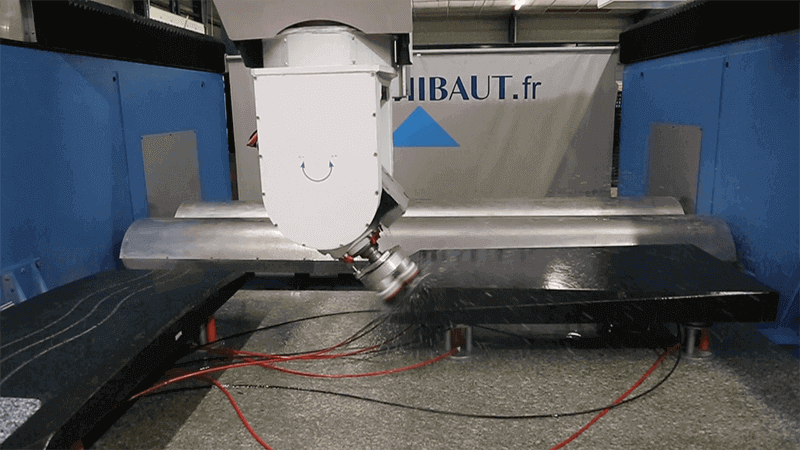

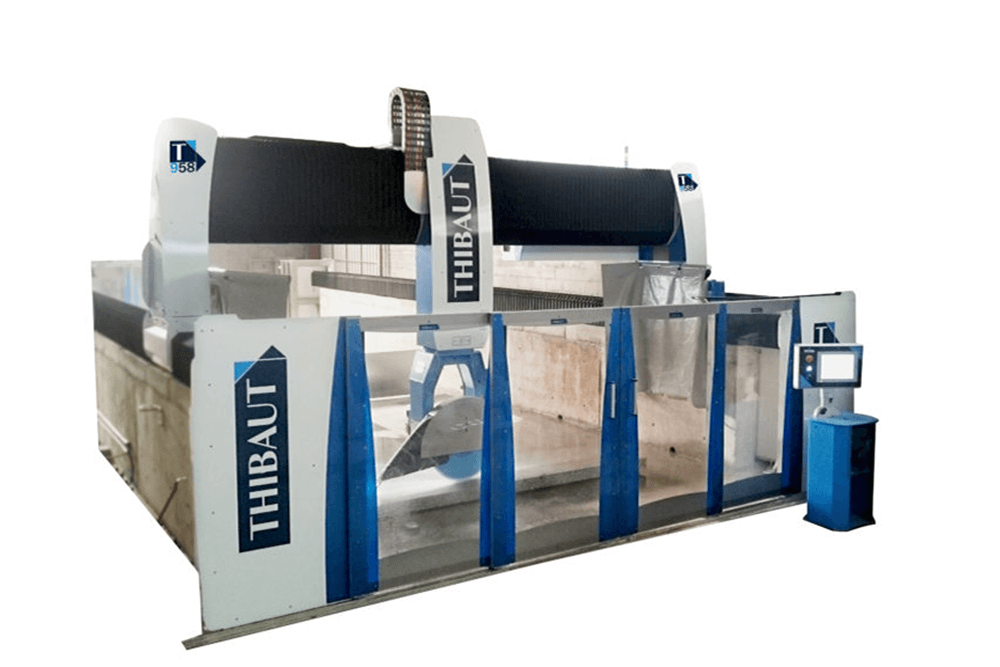

Introduction The stone industry has experienced a significant transformation with the introduction of 5-axis bridge saws. Among the leaders in this field, THIBAUT stands out for its innovation and quality. In this article, we will explore the advantages of 5-axis bridge saws for stone, the unique features of THIBAUT machines, and how they can revolutionize […]

Read moreIntroduction to 5-Axis Cutting The 5-axis cutting technology is a major innovation in the ceramic and stone cutting industry. Unlike traditional cutting machines, 5-axis machines like the THIBAUT TC425 offer unparalleled flexibility and precision. This technology allows for complex cuts and sophisticated shapes, ideal for kitchen and bathroom countertops. Thanks to multi-directional cutting capability, professionals […]

Read moreWe are delighted to inform you that Thibaut, a leader in stone processing machinery, will be participating in Stone+tec 2024, which will take place from June 19th to 22nd in Nuremberg, Germany. This prestigious event brings together experts from the natural stone and stone technology fields, providing a unique platform for idea exchange, discovering new trends, and showcasing the latest […]

Read more