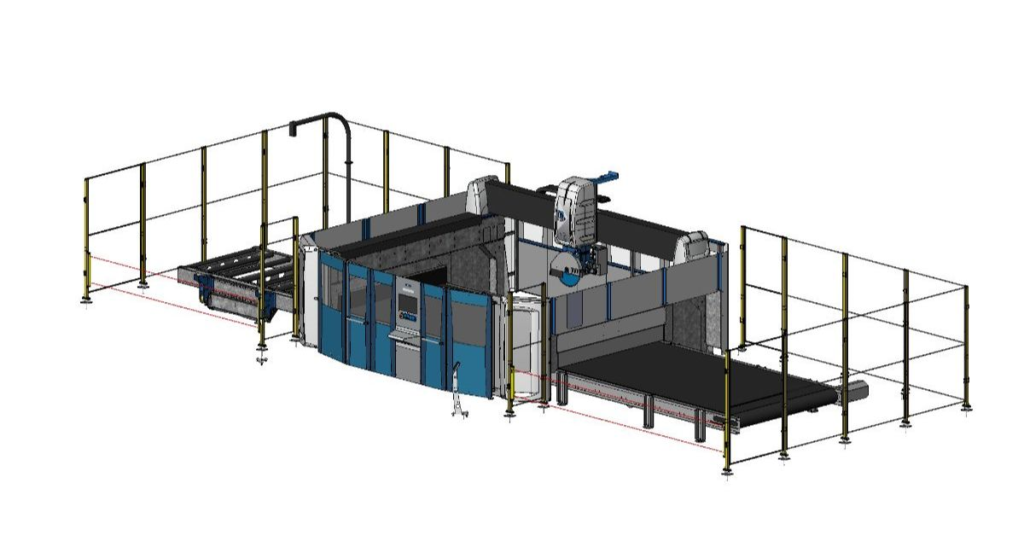

If you're looking for productivity and peace of mind to focus on growing your business, this 5-axis numerically controlled cutting machine is your solution. The 5-axis bridge saw TC625 offers advantages that are unique in the market:

| ADAPTS TO YOUR NEEDS Monobloc => cheaper M (Mechanically welded structure) => more ergonomic, the operator can move around the table TOPS => more productive thanks to its conveyor belt and automatic loading table on trestles SAVINGS Up to 20% savings on materials. The ACS (jigsaw) allows you to make the most of the slice, for example by cutting an L-shaped work surface without having to move it or by finishing cutting at right angles. It also allows you to have a smaller worktable, as there is no need to move the pieces to complete the cuts. |

| PRODUCTIVITY AND SPEED Thanks to the speed of its axes, the machine can remove up to 12 ceramic kitchen worktops in 8 hours. SOLIDITY THIBAUT machines are more robust and their weight reduces vibration and tool wear. We have seen a 10% saving in tool wear. |

It is made with a mitre cut at 45° and straight cuts at 90° with a special program for Dekton and Ceramic (thickness: 2 cm). Deceleration at the entry and exit of the disc on the boards.

If you want to know more, TC625

Introduction The stone industry has experienced a significant transformation with the introduction of 5-axis bridge saws. Among the leaders in this field, THIBAUT stands out for its innovation and quality. In this article, we will explore the advantages of 5-axis bridge saws for stone, the unique features of THIBAUT machines, and how they can revolutionize […]

Read moreIntroduction to 5-Axis Cutting The 5-axis cutting technology is a major innovation in the ceramic and stone cutting industry. Unlike traditional cutting machines, 5-axis machines like the THIBAUT TC425 offer unparalleled flexibility and precision. This technology allows for complex cuts and sophisticated shapes, ideal for kitchen and bathroom countertops. Thanks to multi-directional cutting capability, professionals […]

Read moreWe are delighted to inform you that Thibaut, a leader in stone processing machinery, will be participating in Stone+tec 2024, which will take place from June 19th to 22nd in Nuremberg, Germany. This prestigious event brings together experts from the natural stone and stone technology fields, providing a unique platform for idea exchange, discovering new trends, and showcasing the latest […]

Read more