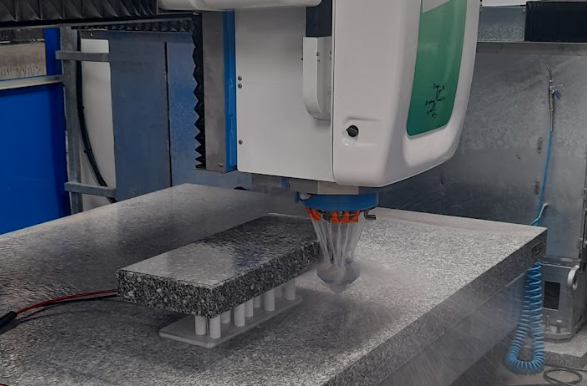

The fourth axis for finishing: Thanks to its rotation axis, the machine can control angle drives for edge polishing, side grooving (drip edge), disc sawing, or inclined engraving.

XXL working capacity:

L version: Optimized for wide decorative sections.

XL version: Allows you to machine very long pieces (bar counters, architectural elements) or to work in pendulum mode on two separate areas.

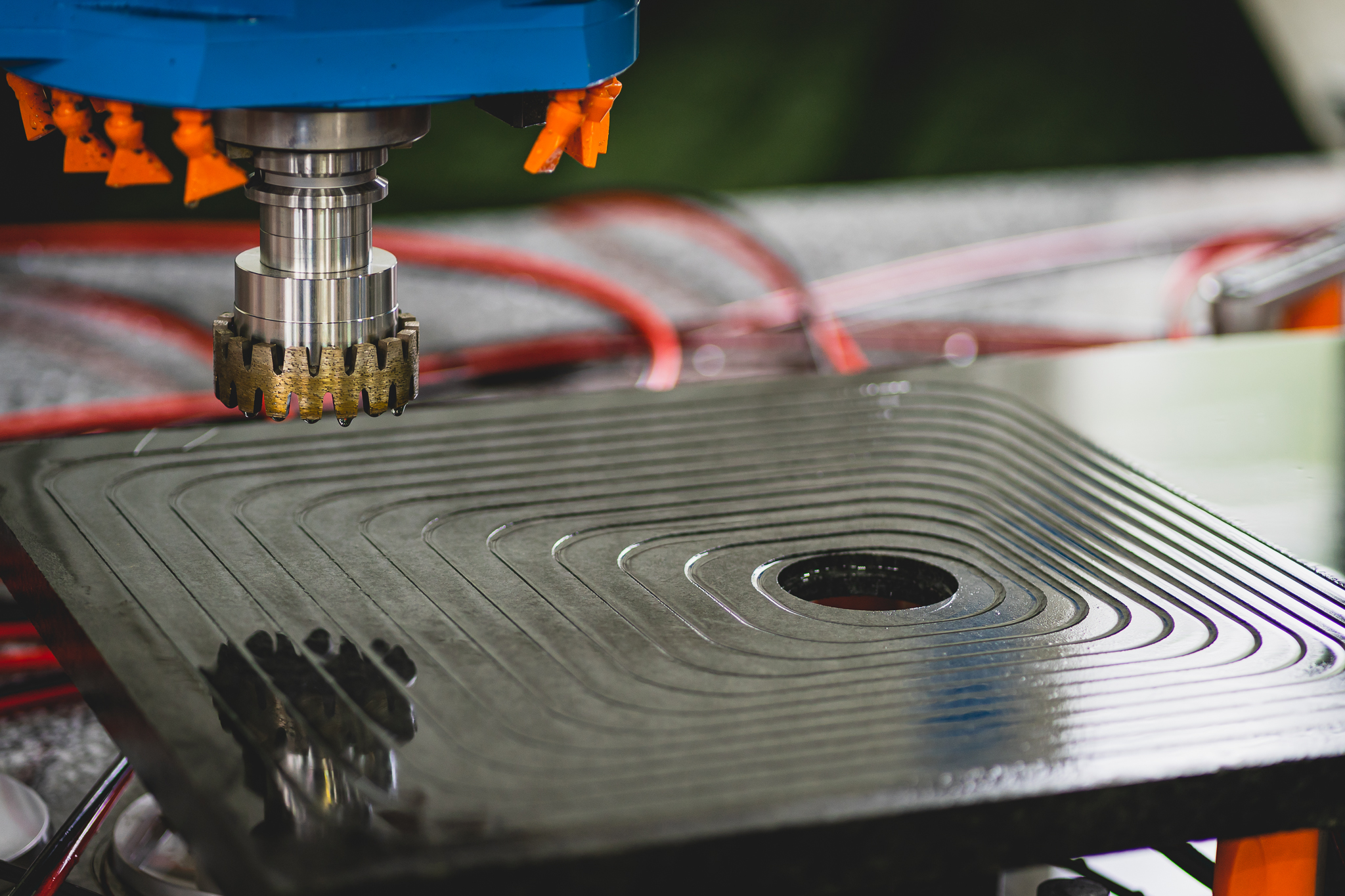

Machining complex profiles: Produce moldings, corbels, and rounded edges with industrial-grade polishing quality thanks to the precise control of the 4th axis.

Intelligent automation V5: Automatic tool change including angle heads for complete autonomy of the manufacturing cycle.

This is the “no compromise” machine. Where a 3-axis model stops at the surface, the 4-axis T812 V5 takes care of the edges and details. Available in L or XL versions, it allows you to take on projects that your competitors cannot handle due to lack of space or technical expertise. It is the central production tool that showcases your expertise on high value-added parts.

| Axes | 4 |

|---|---|

| Tool magazine | 49 |

| Software(s) | Pilot, T'Art, eT'CAM, T'CAD T'CAM |

| Spindle power | 16,2 kW (S6) |

| Spindle rotation speed (rpm) | 0 - 10 000 |

| Pressure | Pneumatic |

| X-axis travel | 3 380 mm |

| Y-axis travel | L : 1 600 mm / XL : 2 000 mm |

| Z-axis travel | 470 mm |

| Table dimensions | L : 3 375 x 1 500 mm / XL : 3 375 x 1 840 mm |

| Tools | BT40 |

| Air supply | 12 m3/h > 6 bar |

| Power supply | 21 kW / 28,5 hp |

| Lubrication | Centralized & automatic |

| Overall dimensions | L : 6 380 x 3 940 x 2 650 mm |

| Weight | L : 7 000 kg |

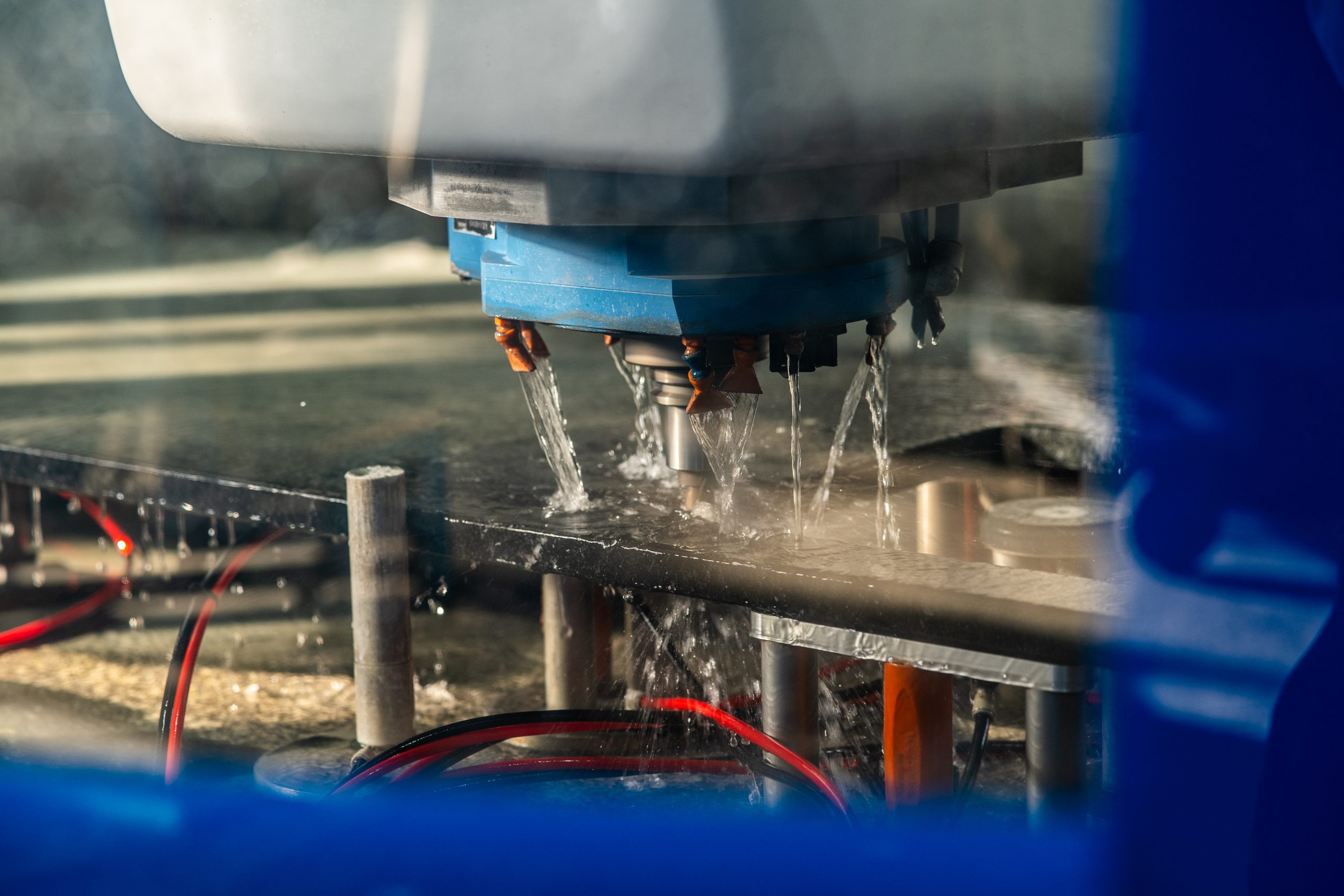

| External coolant | 40 l/min |

| Internal coolant | 20 l/min |

Loading...